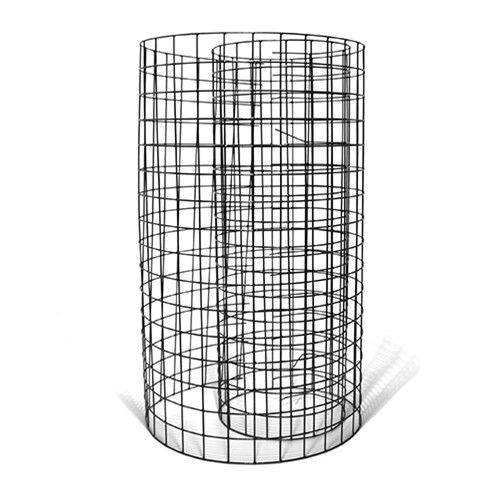

Steel Grating

Steel grating introduction

The grating plate is a steel product made of flat steel that is cross-arranged at a certain interval and cross bars and welded into a square grid in the middle. It is mainly used for ditch covers, steel structure platform plates, steel ladder treads, etc. The cross bars are generally made of twisted square steel.

Generally, it is made of carbon steel and hot-dip galvanized on the surface to prevent oxidation. It can also be made of stainless steel. Steel grating has the properties of ventilation, lighting, heat dissipation, anti-slip, explosion-proof, etc.

Classification

1. According to the welding method, it can be divided into: pressure welding type, interlocking type, locking type and penetration welding type.

2 According to the shape of the side surface of the load-bearing flat steel, it can be divided into: plane type, tooth type and “I” type, etc.

3. According to its use, it can be divided into: general-purpose steel grating plates and special-purpose steel grating plates such as: trench covers, step plates, etc.

4. Steel grating plates are divided into stainless steel grating plates and carbon steel grating plates according to materials.

Production method

1. The press-welded steel grating is made of load-bearing flat steel and cross bars arranged at a certain interval, welded into the original plate using 200-ton hydraulic resistance welding automation equipment, and processed into the product required by the customer through cutting, hole opening, hemming and other processes.

2. Load-bearing flat steel spacing: The center distance between two adjacent load-bearing flat steels is usually 30MM and 40MM.

3. Cross bar spacing: The center distance between two adjacent cross bars is usually 50MM and 100, which can be produced according to customer requirements.

4. Various types of steel gratings can be customized according to customer requirements

Features

1. High strength and light weight;

2. Strong anti-corrosion ability and durable;

3. Beautiful appearance and glossy surface;

4. No accumulation of dirt, rain, snow or water, self-cleaning and easy to maintain;

5. Good ventilation, lighting, heat dissipation, anti-slip and explosion-proof properties;

6. Easy to install and disassemble.

Common product specifications (customized sizes accepted)

1. Vertical bar spacing: conventional 30, 40, 60 (mm); non-standard spacing: 25, 34, 35, 50, etc.;

2. Horizontal bar spacing: conventional 50, 100 (mm); non-standard spacing: 38, 76, etc.;

3. Width: 20-60 (mm);

4. Thickness: 3-50 (mm).

Application

Widely used in platforms, walkways, piers, ditch covers, manhole covers, ladders, fences, factory construction, etc. in the fields of petrochemical, electric power, tap water, sewage treatment, ports and terminals, building decoration, shipbuilding, self-propelled parking lots, municipal engineering, sanitation engineering, etc.

Customized Sizes Accepted