3D Welded Galvanized Wire Mesh Panels For Construction

| Material: | Galvanized Wire | Application: | Mainly Used In Construction |

|---|---|---|---|

| Customer Made: | Yes | Feature: | Thermal Insulation, Fireproofing |

| Technique: | Professional Welding | Factory: | Yes |

3D Welded Mesh Panel used in construction with high tensile strength

Quick Detail:

3D panel, a new wire mesh product, is mainly used in construction. High tensile and easy installation make 3d wire mesh panels become very popular according to our construction customers both at home and abroad.

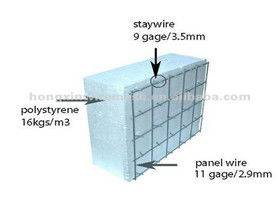

3d panel, also called double layer welded wire panel, joins two pieces of welded wire panel together through welding method. The side panel mesh is commonly 2″ opening with 11 or 12 gauge wire, surface with galvanized wire panel or hot dip galvanized wire panel. Inserted EPS size is 2″, 2.5″ and 4″.

Components of the installed panel include:

- Foam core for insulation.

- Wire mesh on inside and outside.

- Welded truss of wire cross pieces.

- Sprayed concrete on both sides (“shotcrete”).

Benefits of 3D Panel: Thermal Insulation, Fireproofing, Moisture proofing, Soundproofing, Lightweight, Economical Efficiency, Shortening of Construction Time.

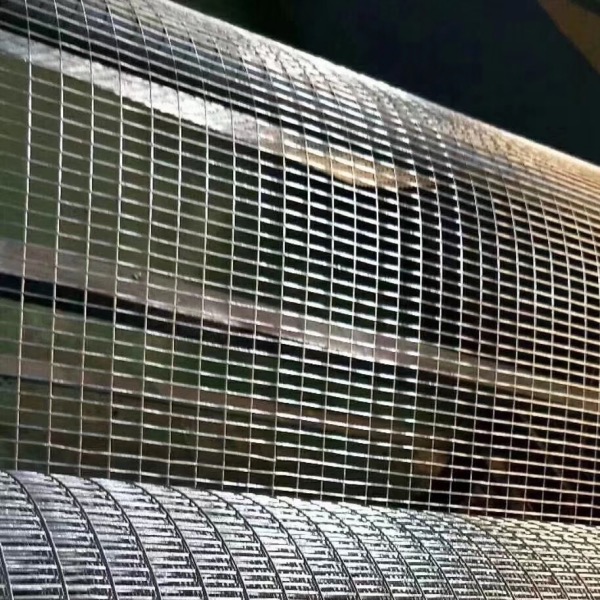

We also supply zinc plated mesh panels used for 3d panels:

- Diameter of the wire 3.5mm, 3.0mm, 2.5mm, 2.0mm.

- The points of mesh crossing is welded firmly and the edges are perfect in order not to have injuries when working with them.

- 20, 25 or 30 panels per package, the end of the packaging is on a pallet.

The most popular sizes:

- 3D wire mesh panels 2, 2.5 and 4 inch welded mesh with polyurethane core.

- 2 inch opening with 11 gauge wire, surface with galvanized wire panel, and inserted EPS size is 2 inch.

- 3D extra reinforcement welded mesh panels used as a floor or roof.